Mr. Zeng:+86 18380488966Mr. Qin:+86 13518116291

Mr. Zeng:+86 18380488966Mr. Qin:+86 13518116291

Mr. Zeng:+86 18380488966Mr. Qin:+86 13518116291

Mr. Zeng:+86 18380488966Mr. Qin:+86 13518116291

SIM mechanism

| Timely identify and respond to problems, shorten the time required to solve production issues; Problems that cannot be solved from the bottom up, upgrading layer by layer; Promote cross departmental communication and improve production efficiency; Inspire employees' sense of participation and responsibility, and enhance the cohesion of the company; Data collection, analysis, and continuous improvement. |

Product QR code

| Workshop production, scan codes to view pictures, and report; Quality inspection, scanning code inspection, drawing pictures, and problem recording; Finished products entering and leaving the warehouse, scanning for storage and shipping; On site after-sales service, scanning codes to view pictures, and checking product production process information. |

Working hour database

| Work hour scheduling

|

Automatically generate product labor data on ERP through BOM list; Calculate the workload of the orders placed in advance and predict the peak and valley production values for future periods. | Utilize working hours to calculate production scheduling for weekly/monthly plans; Using working hours for daily production planning and scheduling is different from traditional manual estimation of workload. |

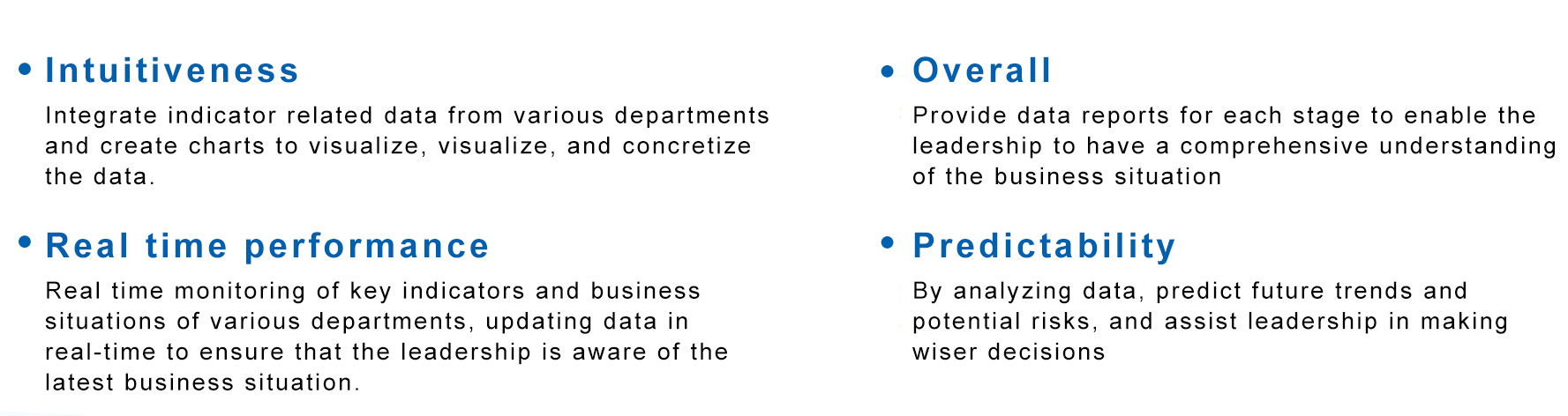

Cockpit Kantan